Analysis: How Will Material Scarcity Affect EV Production?

[ad_1]

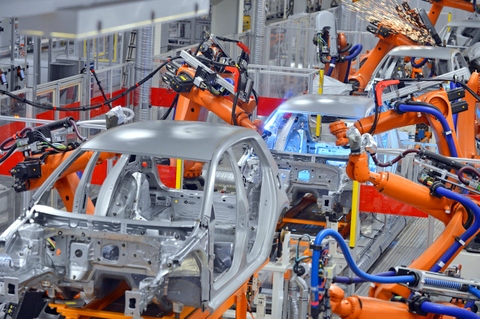

Electric powered Automobile Advancement Is Pushing Materials Needs

When most persons imagine about quick techniques to cut down their carbon footprint, just one of the most common suggestions is to replace their gas-guzzling each day driver with an electrical car. Buying an EV is relatively simple, if a little bit additional expensive than an inner combustion engine car or truck, but that may possibly not be the situation in the foreseeable future. How will substance shortage influence EV production going forward?

Having difficulties With Semiconductor Shortages

Most of the fashionable technologies that helps make the entire world purpose relies on semiconductors. With out these materials, it’s unachievable to produce the chips that make every thing from cellphones to EVs work.

The chip shortage commenced in 2020 due to trade conflicts amongst the United States and China and was made worse by the COVID-19 pandemic. Most of the world’s chip producing capabilities exist in Asia.

Gurus estimate that the chip shortage will probably go on by means of 2023 and into 2024 in advance of factors start to even out. The chip shortages are now hitting the gear employed to manufacture the chips, main to even more offer troubles and building it tougher to satisfy the increasing demand.

Lacking Some Essential Materials

The COVID-19 pandemic brought on all types of things to vanish from retail store shelves, starting off with cleaning products and bathroom paper and biking by way of every thing from soda to cream cheese and infant system over the very last two years. Even beer disappeared from retail outlet shelves as firms contended with an aluminum scarcity.

It could possibly not seem to be as important as the semiconductors utilized to make laptop chips or the exceptional earth metals utilized to make EV batteries, but an aluminum shortage can be as impactful. Extruded aluminum is a well-liked selection for automotive producing simply because it permits engineers to style strong and lightweight frames. With out aluminum, makers may possibly be pressured to return to steel for their design, which will reduce the selection of EVs, creating them a lot less successful overall.

Battery Raw Materials Shortages

An EV is only as fantastic as its battery and the supplies needed to develop the significant lithium-ion battery packs that power these autos are in short source. It’s getting to be additional and more tricky to harvest and refine the manganese, nickel and lithium vital to make these batteries.

At the moment, the world’s battery creation is a single-tenth of what it requirements to help anticipated EV development about the subsequent many years. Some in the automotive marketplace worry that if new answers are not identified, these shortages won’t just slow the adoption of EVs—they could cease it totally.

Securing the Upcoming of EVs

There are potential answers on the horizon. Tesla, for case in point, just lately used for a allow to open up a processing plant in Texas that can refine spodumene concentrate into usable lithium hydroxide for its EV batteries.

Nonetheless, there is not now ample offer to aid the ever-escalating demand. Suppliers will want to uncover new remedies if they hope to make EVs more obtainable to the masses.

Additional EV Information:

Tesla Opens New Plant Claims New Product

Welcome to the 12 months of the EV

[ad_2]

Resource website link