Electronic assemblies without PCBs – Electronic Products & TechnologyElectronic Products & Technology

Laser direct structuring (LDS) is a unique results story. For practically 20 yrs, it has been possible to utilize digital conductor paths specifically onto plastic elements all through sequence production. LDS permits the creation of electronic assemblies with versatile geometric designs. This approach enables digital goods (this sort of as smart telephones, sensors or healthcare equipment) to come to be even lesser and far more effective. Automatic production procedures also make this procedure extra economically desirable.

There is much less and much less room obtainable for digital assemblies, so alternatives are wanted which change standard printed circuit boards. LDS enables even more miniaturization and would make increasingly complicated geometric types possible. This is a steady and trusted approach that has founded alone in good quality-crucial sectors these as professional medical technological know-how or safety-suitable parts for the automotive marketplace.

LDS system allows three-dimensional assemblies

Immediate laser structuring allows 3D-MID (Mechatronic Built-in Gadgets) assemblies to be manufactured. When utilizing 3D-MID, electronic elements can be equipped specifically on to a 3-dimensional foundation physique, without circuit boards or connecting cables. The foundation system is created making use of an injection moulding course of action, whereby the thermoplastic substance has a non-conductive, inorganic additive.

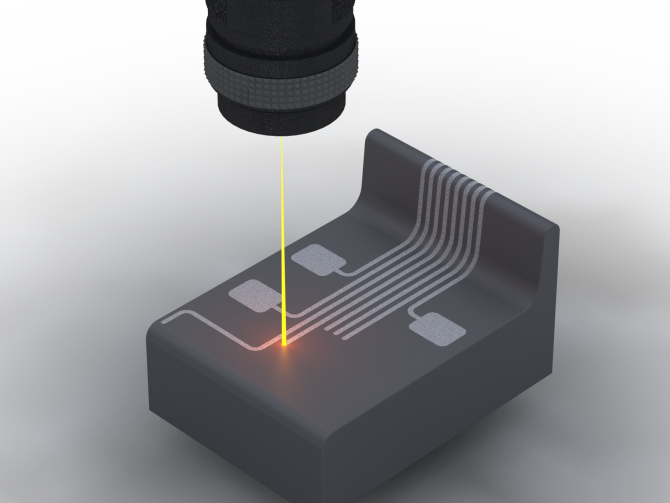

The framework of the conductor path is used utilizing the LDS process.

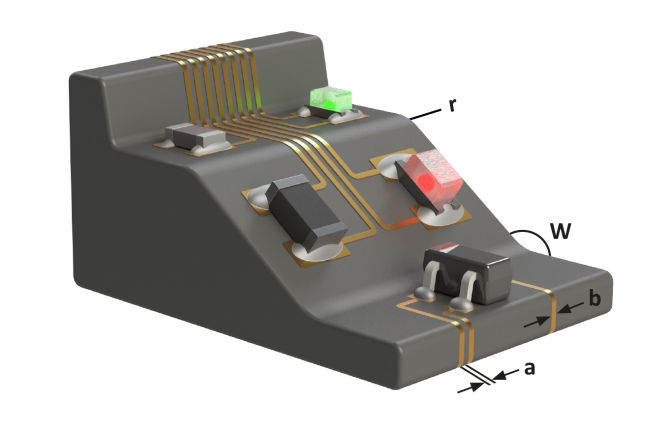

LDS allows electronic assemblies to be designed in flexible geometric shapes. Good telephones, listening to aids and wise watches are turning out to be more compact and extra strong many thanks to this method. Source: Harting

The additives in the content are “activated” by immediate laser structuring so that the plastic product can accommodate the electrical conductor paths. The laser beam writes the areas meant for the conductor paths and produces a micro-tough framework. The released steel particles variety the nuclei for the subsequent chemical metallisation. In this way, the electrical conductor paths are applied to the places marked by the laser. The other areas of the a few-dimensional foundation system stay unchanged. The plastic part can then be assembled in typical SMD procedures very similar to a conventional PCB. It is also ideal for soldering in a reflow oven.

Multipurpose application of laser technologies

As one of the greatest suppliers of 3D-MID components outside of Asia, HARTING uses significant-performance laser devices for the LDS approach, with 3 lasers performing in parallel, every offset by 45 degrees. Many thanks to an additional axis of rotation, components can be processed by the laser at the same time from all sides (360 degrees). This technologies enables versatile geometric designs, this kind of as reflector shells or LED lights, to be made. Despite the negligible conductor path thickness of 16 to 20 μm, the conductor paths are nevertheless suitable for demanding automotive factors or for applications with currents up to 10 A – for case in point for heating coils in cameras which are applied to reduce the optics from fogging up

Least distances among the conductor paths (a): 50 – 150μm. Bare minimum width of the conductor paths (b): 50 – 150μm Radius (r): .2mm. Resource: Harting

Frequent improvements throughout the electronics improvement phase or new factors with modified proportions can lead to high priced changes for the duration of traditional PCB manufacturing. The laser layout, in contrast, can be tailored quite flexibly by employing the parameters of the laser’s control application. No modifications in the injection moulding are necessary for this.

The production of prototypes using LDS is also easier in contrast to regular procedures. HARTING can deliver the plastic base entire body using LDS-suitable content and 3D printing. Injection moulding can also be employed with affordable prototype applications.

New traits in the LDS method

Several elements of LDS engineering have been enhanced and even further produced about the earlier couple of years.

- The performing place of the laser has been enlarged from 160 x 160 x 80 mm to 200 mm x 200 mm x 80 mm, so enabling a higher packing density and the processing of even larger factors.

- The doing the job velocity of the laser can be doubled to 4 m/s by optimizing the servo units and mirrors which guide the laser beam, thus significantly lessening the processing time.

- The advancement of the optics enables the use of a laser with a diameter of 100 μm and a laser with a high-quality concentration of 50 μm for processing even smaller sized buildings.

HARTING is the only 3D-MID manufacturer in the entire world that has a laser method with three high-quality emphasis optics of 50 μm. Even smaller sized conductor route gaps can be realized many thanks to this high-quality target laser. Therefore, lots of conductor paths can be developed on the identical ingredient and a increased packing density can be executed. This is employed for protection technologies, amid other issues, mainly because the intently spaced and intertwined conductors are capable of triggering basic safety alarms from even the smallest bodily interference.

Innovations in elements and economics

Only specifically selected thermoplastics are licensed for the LDS approach these are obtainable from inventory. The system can be even more enhanced with consumer-particular changes to the plastic materials:

- HARTING takes advantage of a method which provides LDS additives to non-accredited products to make them MID-suitable.

- Precise RAL or Pantone colours can be reached with MID plastics by employing colour pigments and exclusive LDS additives.

- By choosing appropriate additives, unique RF properties can also be executed, depending on the frequency selection.

Electronic factors – these as LEDs, ICs, photodiodes and sensors – can be attached straight on to the part provider. The assembled component carriers can then be processed as typical SMD components. Supply: Harting

To more improve the charge-effectiveness of the producing procedure, HARTING depends on automatic robotic devices. The LDS laser program is outfitted with a rotary indexing desk so that a ingredient can be inserted or eradicated although another part is continue to being processed. The in-feed and unloading strategies are automatic by HARTING working with robotics. This increases throughput and autonomy, although also enabling integration into automatic manufacturing procedures. An more automation action is offered during the injection moulding approach. In this article, much too, a robot usually takes about the elimination of the injection moulded elements. The use of robotics also enhances the exact reproducibility of the procedures and, so, overall solution high quality.

Additional expansion for 3D-MID

The 3D-MID caps secure the electronics from unauthorized access the two mechanically and electronically. A highly specific meandering composition detects each individual entry, no issue how smaller, and as a result stops theft. Resource: Harting

HARTING reports enhanced demand for MID tasks and has further more expanded the 3D-MID division by investing in equipment and by attaining a competitor’s enterprise. Impressive in-dwelling items are also contributing to more advancement. HARTING has produced a remedy based on 3D-MID technological innovation which replaces flexible PCBs with a part carrier. As an alternative of using a flex-PCB, the element provider can be fitted instantly with digital parts, consequently saving up to two thirds of the cost.

—————————————-

About HARTING 3D-MID

HARTING 3D-MID is presenting the finish worth chain for 3D-MID technologies from a solitary source, which include advancement/prototyping of purchaser-particular goods, injection moulding, laser immediate structuring, metallization, assembly and link technologies, as very well as remaining inspection. Its core business is the production of mechatronic components for automobile manufacturing, market, medical technologies and sensor programs.

Dirk Rettschlag, project supervisor & IE MID at Harting MID.